What are the major components of metal stamping production?

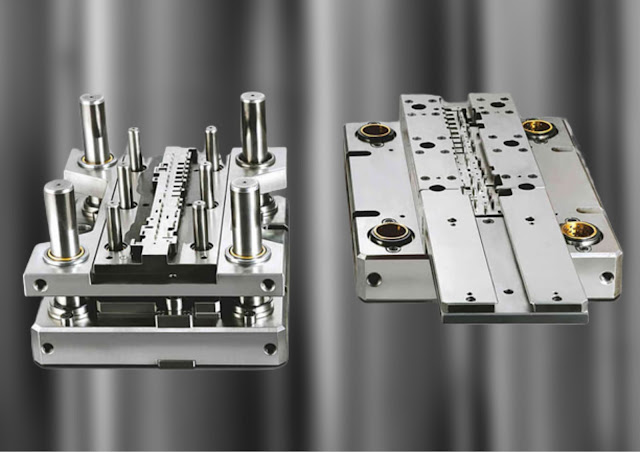

Metal stamping production is now offering a lot of benefits to different industries. It is providing them with high-quality components that can be used for the further production of the required machinery or items. Metal stamping, commonly known as pressing, is a low-cost manufacturing process that aims to produce high volumes of identical metal components. The operation is suitable for both short and long-term production. The process consists of a lot of steps like coining, punching, blanking, pending, embossing, and flanging. When everything is done in the right manner, you will be able to achieve high-quality products. Metal stamping machines can do more than just the stamping job. They can easily punch, cast, cut, and shape metal sheets. The machines are actually programmed or CNC-controlled to provide high repeatability and precision for each stamped piece. Given the use of metal stamping in different industries, there is now a huge demand for companies that can complete the job

.jpg)